Increased consumption such facilities is performed in hotels, where it becomes the principal, reaching 24% of total energy consumption. Consumption in hospitals is 17% and finally there are the sports centers with swimming pool and the educational centers, where the percentages not in any case exceed 15%.

Currently DHW service is a necessity of the first order in the housing facilities, as well as cold water service.

In the other buildings such as offices, supermarkets, hypermarkets and small businesses, are not representative consumption.

Regulatory trends in these systems are:

The incorporation in the Technical Building Code (CTE) of the obligation to install solar energy for heating domestic hot water, reducing the consumption of fossil fuels.

Regular inspection of boilers more than 15 years, to meet the requirements specified in the Regulation of Thermal Installations in Buildings (RITE).

Obligation to comply with the rules of Energy Labelling for water heaters and warehouses hot water.

The hot water boiler should be regularly reviewed. An annual review is recommended for proper performance. A dirty boiler has difficulty combustion and therefore has higher consumption.

Regulate temperature for about 45ºC off the taps. If the temperature is more energy being squandered.

Properly insulate distribution pipelines and storage tank, as more than 10% of the total energy can be lost if they are not well insulated.

Perform inspections in plumbing installations helps to detect leaks and over-consumption of water due to breakdowns, achieving significant savings.

Periodically measuring pressures and flow rates at various points of the circuit for obstructions.

Install thermostatic valves on the drive, returns and consumption points to balance the distribution circuit.

Install mechanisms, and water-saving devices. Mentioned for example, the aerators that reduce water flow and, therefore, consumption of fuel used to condition it. The following table summarizes savings rates for different saving mechanisms.

| Description of water economizer system | Flow (l/min) | Normal flow (l/min) | Savings (%) |

| Aerator to sink, bidet and kitchen sink | 8 | 18 | 55 |

| Shower flow restrictor | 13 | 22 | 40 |

| Rotary and fixed, different flows | 9,5 | 22 | 56 |

| 7,4 | 22 | 66 | |

| 6,8 | 22 | 69 | |

| W.C. Stop for cisterns | 3 | 10 | 70 |

| Shower Massage: diffuser 12 holes | 11,8 | 22 | 46 |

| Shower Massage: diffuser 3 holes | 8,4 | 22 | 62 |

| Shower Massage: diffuser 4 holes | 7,2 | 22 | 67 |

| Shower Massage: diffuser 2 holes | 6,6 | 22 | 70 |

| Shower telephone three positions: normal position (rainwater) | 8,5 | 22 | 60 |

| Shower telephone three positions: soft position (champagne) | 8 | 22 | 63 |

| Shower telephone three positions: massage position | 7 | 22 | 68 |

Minimize the distance between the DHW production and consumption, to reduce the path of the pipes and thereby reduce losses.

Incorporate into the pumps:

Static starters that control their activation peaks.

Use asynchronous motors with frequency inverters and get: adjust the flow rate and pressure and saves on power consumption and engine maintenance costs. They are usually amortized over a year.

Install a timer switch to disconnect the recirculation pump stations during nighttime hours (when there is no demand for hot water). You’ll save on electricity.

Harness waste heat from condensation cooling equipment or any other residual energy for heating water.

In case of change of boiler must opt for the installation of condensing boilers and low temperature. They are more expensive, but its performance causes sufficient financial savings to amortize the extra cost over a period of 5-8 years, less than half of the lifetime of the machine. Also worth knowing that the body pressurized boilers consume 20% less energy than atmospheric.

Solar thermal energy is a very interesting option for DHW These facilities are generally sized to provide between 50% and 70% of hot water demanded, and the necessary investment can be amortized in less than half of the service life of equipment.

Pilotless heaters. A pilot flame consumes 13g of gas per hour. The use of gas water heaters without permanent pilot, means a saving of up to 113kg / year, if we speak of natural gas, the figure reaches 120m3 / year.

We perform comprehensive installation projects in the field of plumbing, DHW facilities and sanitation. Including:

plumbing and hot water

- Plumbing for water supply

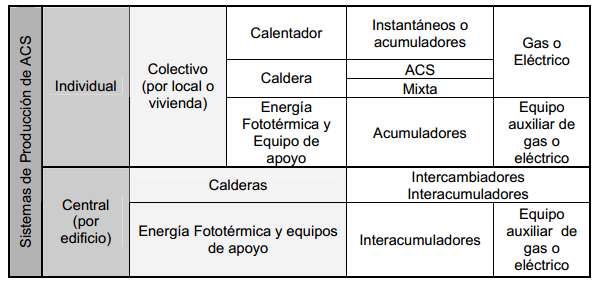

- Installations Hot Water (DHW)

- Water supply and sanitation installations

- Distribution networks

- Installing pressure groups

- Water pumping systems

Counting with approval as Plumbing Licensed Installer.

This post is also available in: Spanish